Next Generation Bipolar Plates for Automotive PEM Fuel Cells

Por um escritor misterioso

Last updated 25 abril 2025

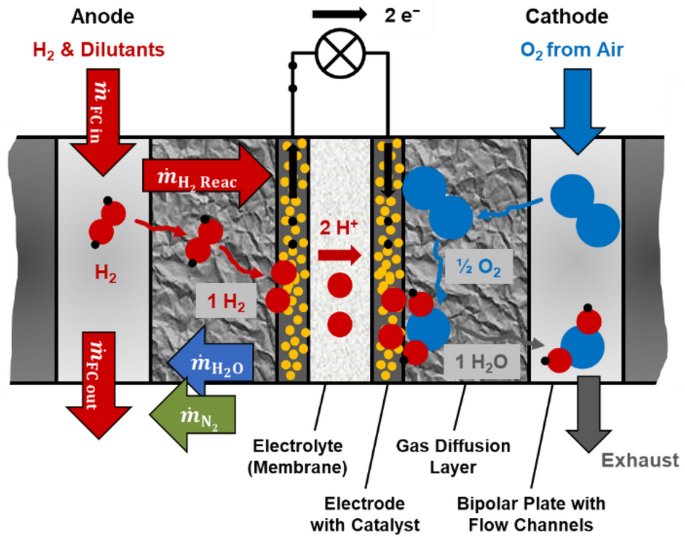

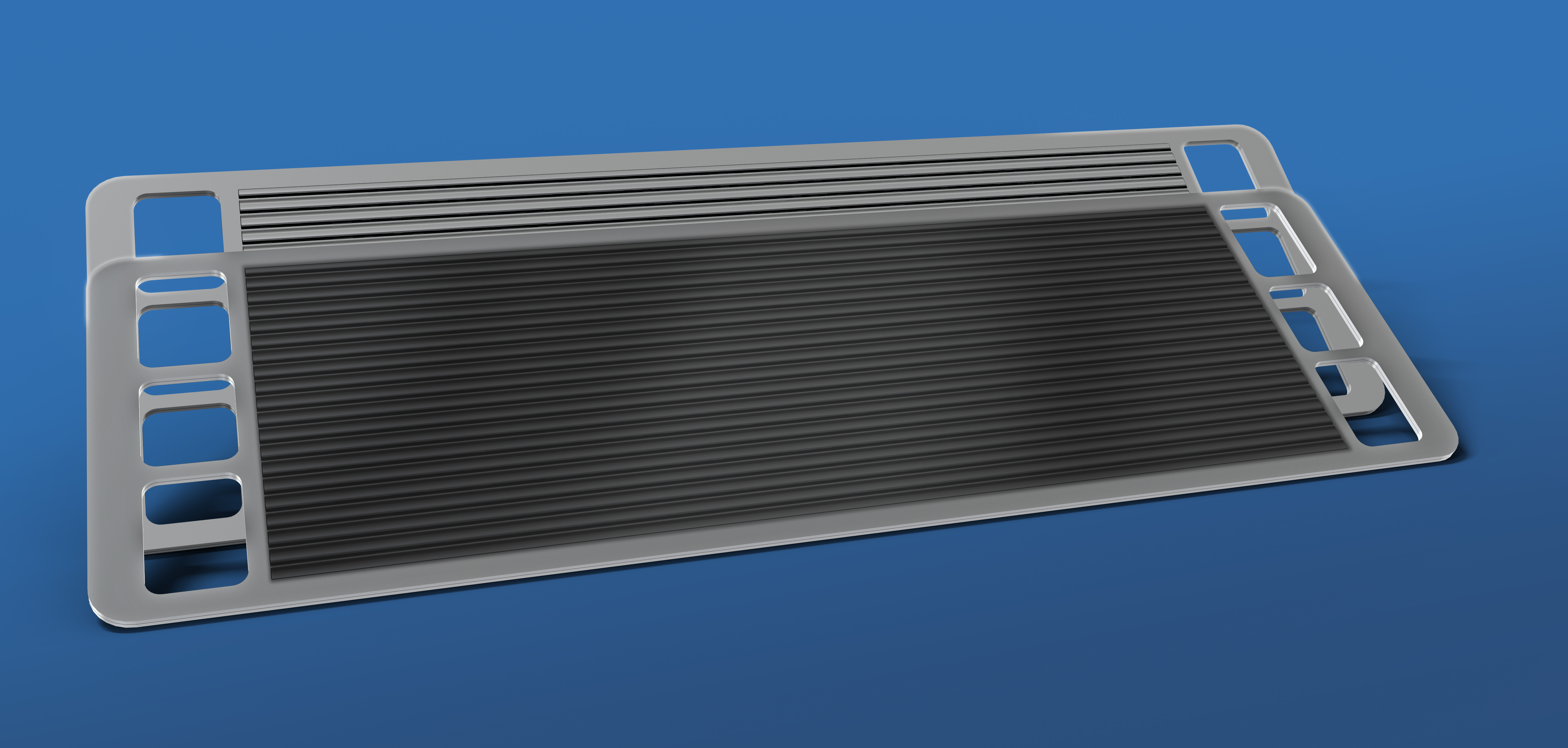

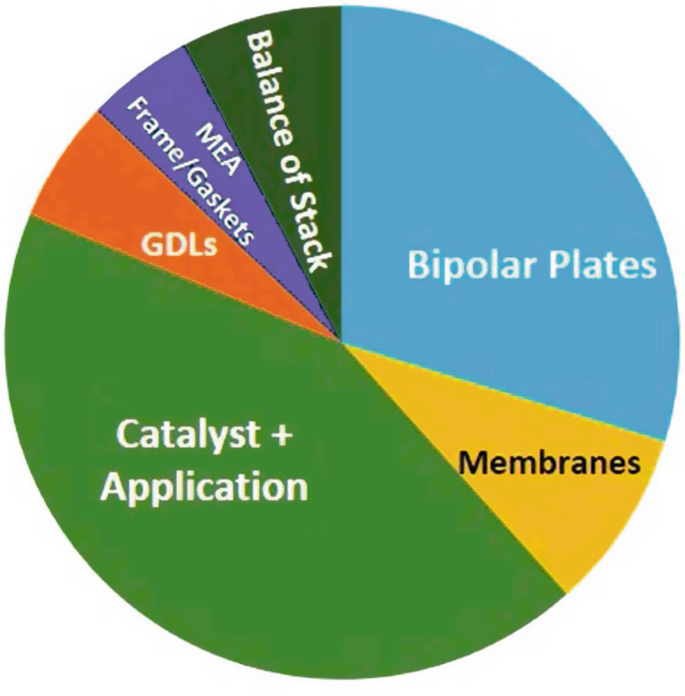

The results of a successful U.S. Department of Energy (DoE) funded two-year $2.9 MM program lead by GrafTech International Inc. (GrafTech) are reported and summarized. The program goal was to develop the next generation of high temperature proton exchange membrane (PEM) fuel cell bipolar plates for use in transportation fuel cell applications operating at temperatures up to 120 °C. The bipolar plate composite developed during the program is based on GrafTech’s GRAFCELL resin impregnated flexible graphite technology and makes use of a high temperature Huntsman Advanced Materials resin system which extends the upper use temperature of the composite to the DoE target. High temperature performance of the new composite is achieved with the added benefit of improvements in strength, modulus, and dimensional stability over the incumbent resin systems. Other physical properties, including thermal and electrical conductivity of the new composite are identical to or not adversely affected by the new resin system. Using the new bipolar plate composite system, machined plates were fabricated and tested in high temperature single-cell fuel cells operating at 120 °C for over 1100 hours by Case Western Reserve University. Final verification of performance was done on embossed full-size plates which were fabricated and glued into bipolar plates by GrafTech. Stack testing was done on a 10-cell full-sized stack under a simulated drive cycle protocol by Ballard Power Systems. Freeze-thaw performance was conducted by Ballard on a separate 5-cell stack and shown to be within specification. A third stack was assembled and shipped to Argonne National Laboratory for independent performance verification. Manufacturing cost estimate for the production of the new bipolar plate composite at current and high volume production scenarios was performed by Directed Technologies Inc. (DTI). The production cost estimates were consistent with previous DoE cost estimates performed by DTI for the DoE on metal plates. The final result of DTI’s analysis for the high volume manufacturing scenario ($6.85 /kW) came in slightly above the DoE target of $3 to $5/kW. This estimate was derived using a “Best Case Scenario” for many of the production process steps and raw material costs with projections to high volumes. Some of the process improvements assumed in this “Best Case Scenario” including high speed high impact forming and solvent-less resins, have not yet been implemented, but have a high probability of potential success.

Development of an ejector for passive hydrogen recirculation in

Next Generation Bipolar Plates for Automotive PEM Fuel Cells

Next Generation Bipolar Plates for Automotive PEM Fuel Cells - UNT

Press News - Reinz Portal

Graphite instead of gold: Thin layers for better hydrogen cars

A comprehensive comparison of state-of-the-art manufacturing

Polymer Electrolyte Membrane (PEM) Fuel Cells: Automotive

Start-up Precors develops innovative coating technology for high

PDF) Metallic Material Selection and Prospective Surface

Fuel Cell EVs Hit the Road

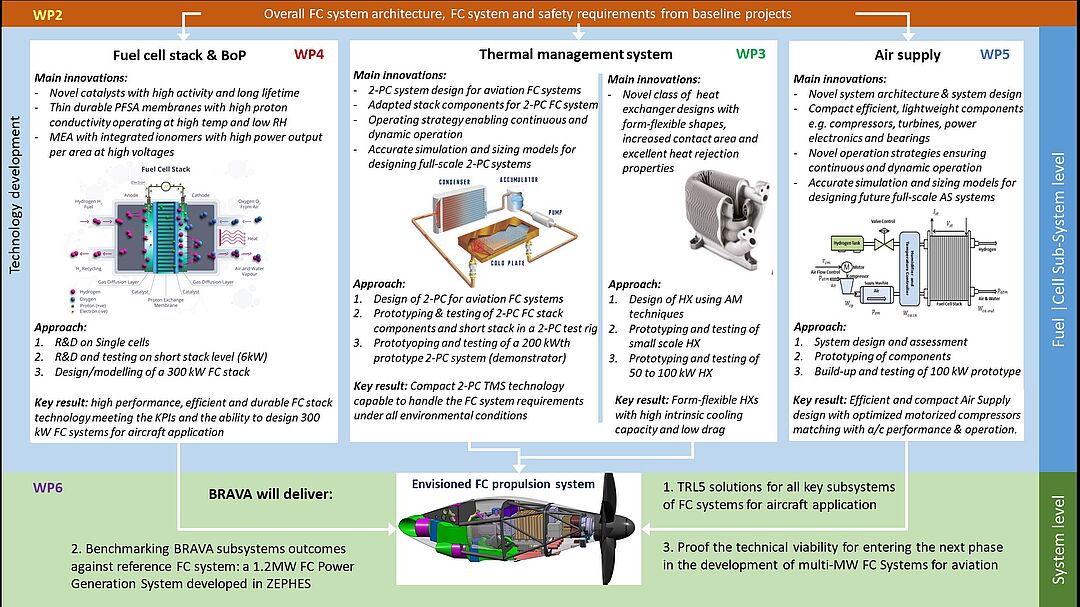

Research Projects

Recomendado para você

-

How do I login? The Online Library25 abril 2025

-

Distance and online learning25 abril 2025

Distance and online learning25 abril 2025 -

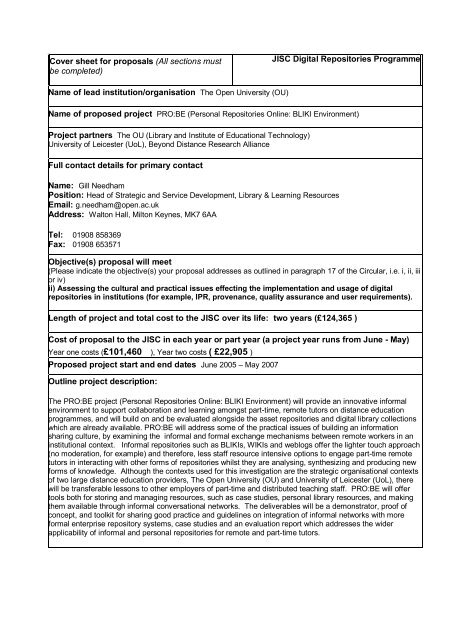

Project Proposal - prowe.25 abril 2025

Project Proposal - prowe.25 abril 2025 -

Utah's Online Library25 abril 2025

Utah's Online Library25 abril 2025 -

University of London - Join us in celebrating #BlackHistoryMonth25 abril 2025

-

The University's library resources include books, journals and e25 abril 2025

The University's library resources include books, journals and e25 abril 2025 -

Utah's Online Library Practice25 abril 2025

Utah's Online Library Practice25 abril 2025 -

Magazines - Minecraft Secrets & Cheats: 100% Unofficial - Lakeland25 abril 2025

Magazines - Minecraft Secrets & Cheats: 100% Unofficial - Lakeland25 abril 2025 -

SAS Libraries School of Advanced Study25 abril 2025

SAS Libraries School of Advanced Study25 abril 2025 -

80 Literature Review Example page 2 - Free to Edit, Download25 abril 2025

80 Literature Review Example page 2 - Free to Edit, Download25 abril 2025

você pode gostar

-

Veja comparativo de Resident Evil 4 no PS5, Xbox Series X25 abril 2025

Veja comparativo de Resident Evil 4 no PS5, Xbox Series X25 abril 2025 -

FCF divulga os finalistas do prêmio “Melhores da Série B 202325 abril 2025

FCF divulga os finalistas do prêmio “Melhores da Série B 202325 abril 2025 -

Pinterest25 abril 2025

Pinterest25 abril 2025 -

JOGO - QUEM É ELA? Coração de Educador25 abril 2025

JOGO - QUEM É ELA? Coração de Educador25 abril 2025 -

Kasparov X Karpov25 abril 2025

Kasparov X Karpov25 abril 2025 -

Final Stage: The Last Initial D Anime Series Airing in Japan25 abril 2025

Final Stage: The Last Initial D Anime Series Airing in Japan25 abril 2025 -

One Piece Anime Heroes Roronoa Zoro Figure Review!25 abril 2025

One Piece Anime Heroes Roronoa Zoro Figure Review!25 abril 2025 -

Setor do Bolsa Família da Secretaria de Assistência Social será reformado e ampliado; empresa já foi escolhida em licitação - Notícias - Prefeitura Municipal de Guanambi - Site Oficial25 abril 2025

Setor do Bolsa Família da Secretaria de Assistência Social será reformado e ampliado; empresa já foi escolhida em licitação - Notícias - Prefeitura Municipal de Guanambi - Site Oficial25 abril 2025 -

baixar o jogo 1001 raciocinio|Búsqueda de TikTok25 abril 2025

-

Download Terraria 1.4.4.9 APK v1.4.4.9 for Android 202325 abril 2025