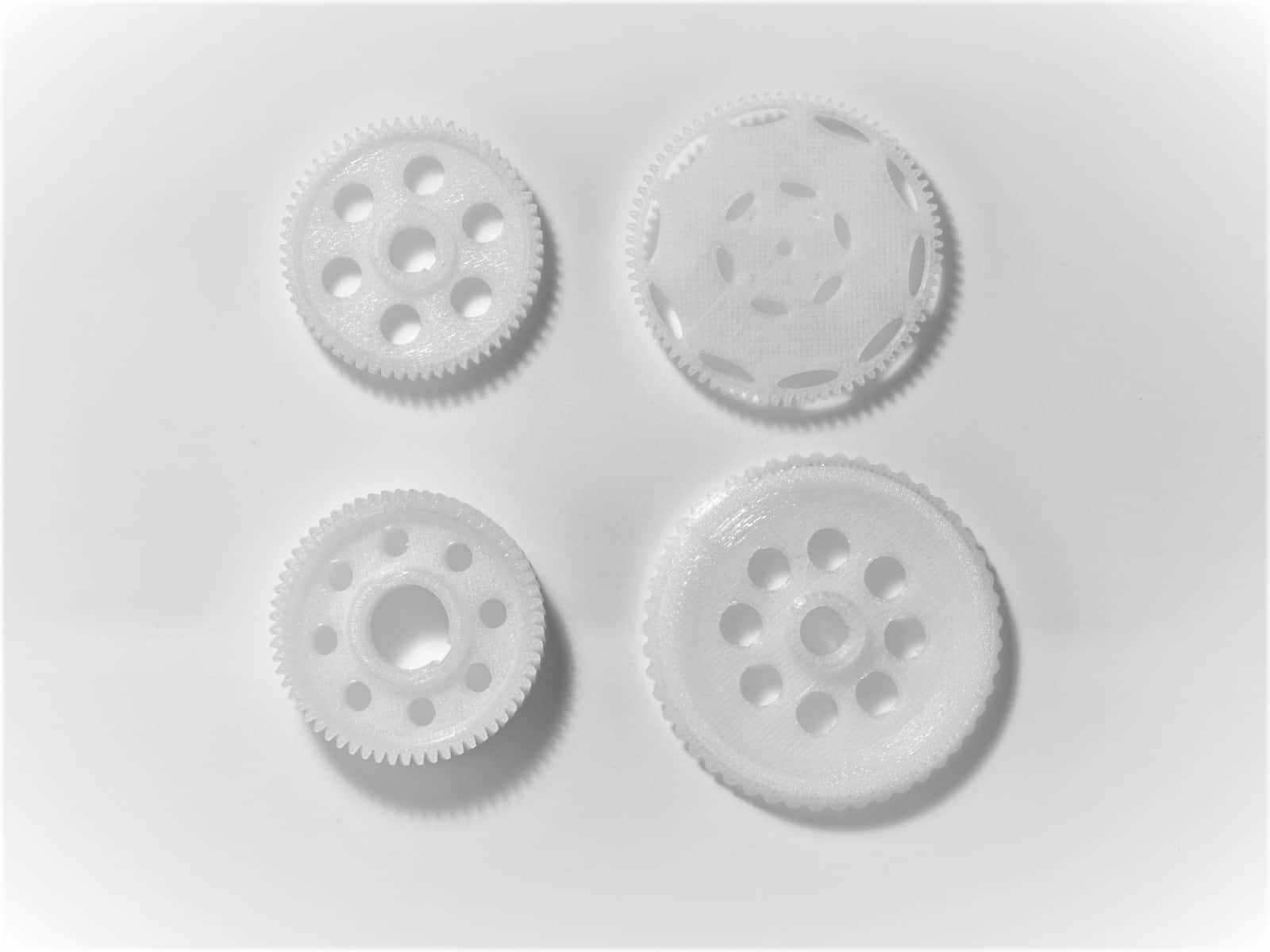

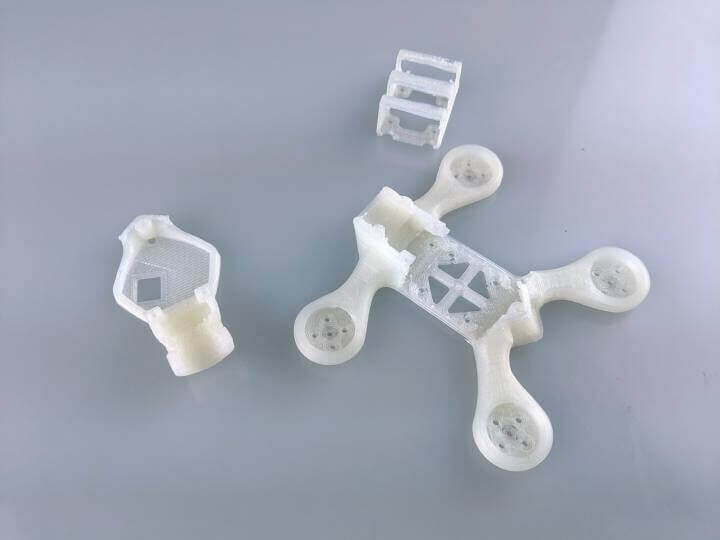

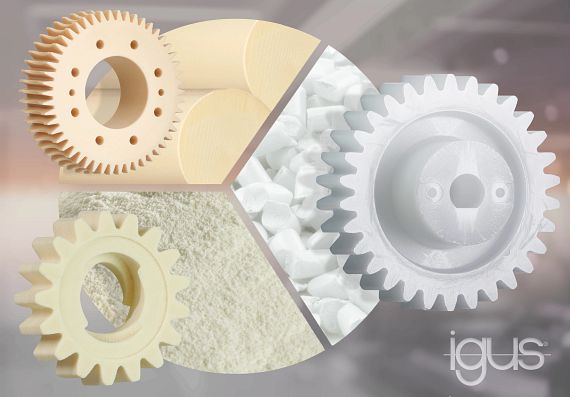

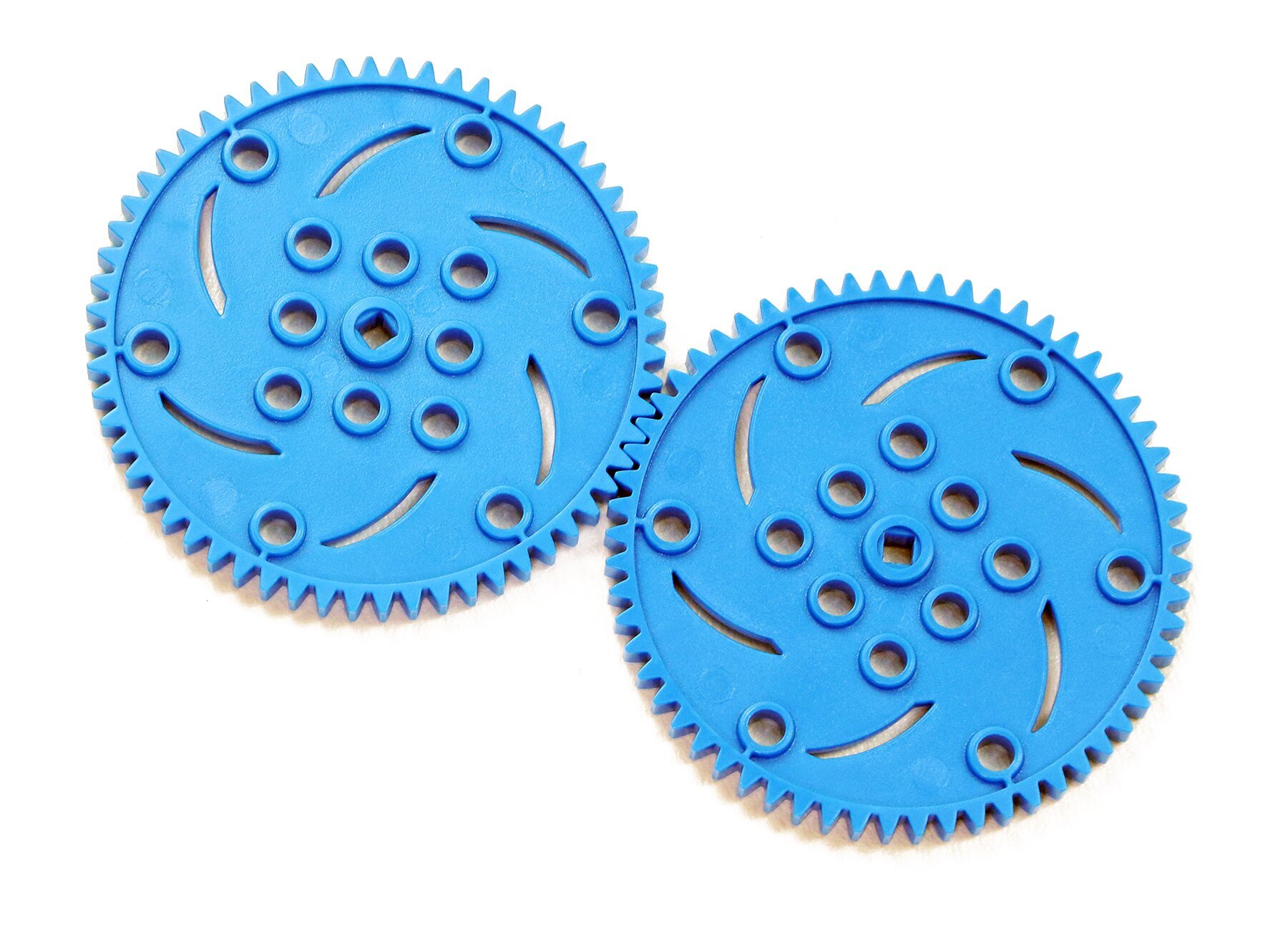

Making Extremely Wear-Resistant Plastic Gears with 3D Printing

Por um escritor misterioso

Last updated 13 janeiro 2025

Using SLS with iglidur® high-performance polymers developed by igus allows manufacturers to make customized plastic gears.

5 Engineering Grade Plastics To Replace PLA - Fusion 3 Design

3D Printing Materials – The Ultimate Guide

Making Extremely Wear-Resistant Plastic Gears with 3D Printing - 3Dnatives

A physical investigation of wear and thermal characteristics of 3D printed nylon spur gears - ScienceDirect

High-Quality Nylon 3D Printing

Introducing Ultimaker PETG - UltiMaker

Nylon for FDM 3D printing (Comprehensive Guide)

Buy plastic gears- igus® UK

When 3D Printing Gears, It Pays To Use The Right Resin

Everything You Need to Know About Nylon Filament for 3D Printing

Recomendado para você

-

Gears Tactics on Steam13 janeiro 2025

Gears Tactics on Steam13 janeiro 2025 -

Buy Gears of War 213 janeiro 2025

-

What Are the Different Types of Gears13 janeiro 2025

What Are the Different Types of Gears13 janeiro 2025 -

Gear - Wikipedia13 janeiro 2025

-

Tribology of gears - About Tribology13 janeiro 2025

Tribology of gears - About Tribology13 janeiro 2025 -

Lab 12 - M.A.D. Box - What are Gears?13 janeiro 2025

Lab 12 - M.A.D. Box - What are Gears?13 janeiro 2025 -

Steampunk Gears from CorsetMakingSupplies.com13 janeiro 2025

Steampunk Gears from CorsetMakingSupplies.com13 janeiro 2025 -

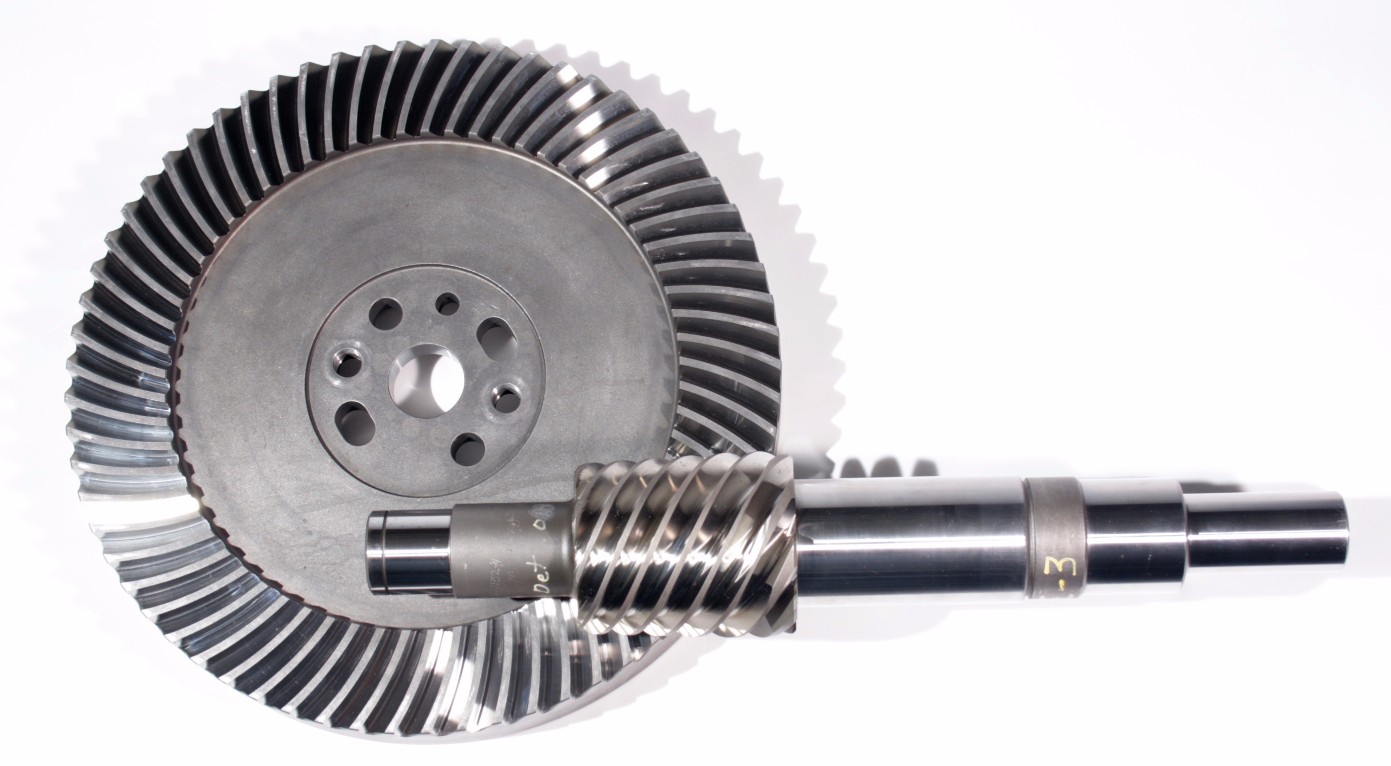

Arrow Gear Products - Bevel Gears13 janeiro 2025

Arrow Gear Products - Bevel Gears13 janeiro 2025 -

Found Objects™ Antique Silver, Copper & Brass Gears by Bead13 janeiro 2025

Found Objects™ Antique Silver, Copper & Brass Gears by Bead13 janeiro 2025 -

![Precision Gears [ Addon ]](https://i.ytimg.com/vi/ufh-uXVOlZU/maxresdefault.jpg) Precision Gears [ Addon ]13 janeiro 2025

Precision Gears [ Addon ]13 janeiro 2025

você pode gostar

-

1 TB SSD Xbox 360 Rgh/jtag Only College Football Revamped 20.113 janeiro 2025

1 TB SSD Xbox 360 Rgh/jtag Only College Football Revamped 20.113 janeiro 2025 -

Vídeo chocante: rato gigante mata pomba após arrastá-la para13 janeiro 2025

-

POKEMON TCG DEOXYS V BATTLE DECK OPENING13 janeiro 2025

POKEMON TCG DEOXYS V BATTLE DECK OPENING13 janeiro 2025 -

Watching my opponent struggle with Qui Gon Gym: a symphony in four movements : r/SWGalaxyOfHeroes13 janeiro 2025

Watching my opponent struggle with Qui Gon Gym: a symphony in four movements : r/SWGalaxyOfHeroes13 janeiro 2025 -

Anjos da morte cartaz anime pintura em tela estilo moderno imagem da parede para sala de estar decoração casa - AliExpress13 janeiro 2025

Anjos da morte cartaz anime pintura em tela estilo moderno imagem da parede para sala de estar decoração casa - AliExpress13 janeiro 2025 -

Stream RinLightWolf Listen to Dream/Nightmare X Listener13 janeiro 2025

Stream RinLightWolf Listen to Dream/Nightmare X Listener13 janeiro 2025 -

Jogos matemáticos para Educação Infantil e Anos Iniciais13 janeiro 2025

Jogos matemáticos para Educação Infantil e Anos Iniciais13 janeiro 2025 -

Slender Patrol Spy Agency 🇺🇦 on X: me doing raid in brookhaven / X13 janeiro 2025

Slender Patrol Spy Agency 🇺🇦 on X: me doing raid in brookhaven / X13 janeiro 2025 -

![𝘋𝘦𝘱𝘢𝘳𝘵𝘶𝘳𝘦! [𝘊𝘖𝘕𝘊𝘌𝘙𝘛 𝘉𝘈𝘕𝘋] (𝘏𝘶𝘯𝘵𝘦𝘳 𝘹 𝘏𝘶𝘯𝘵𝘦𝘳 2011) Sheet music for Trombone, Euphonium, Tuba, Flute piccolo & more instruments (Concert Band)](https://musescore.com/static/musescore/scoredata/g/157354ca3efdc85258d4a953d53254c5d90195d9/score_0.png?no-cache=1582982214) 𝘋𝘦𝘱𝘢𝘳𝘵𝘶𝘳𝘦! [𝘊𝘖𝘕𝘊𝘌𝘙𝘛 𝘉𝘈𝘕𝘋] (𝘏𝘶𝘯𝘵𝘦𝘳 𝘹 𝘏𝘶𝘯𝘵𝘦𝘳 2011) Sheet music for Trombone, Euphonium, Tuba, Flute piccolo & more instruments (Concert Band)13 janeiro 2025

𝘋𝘦𝘱𝘢𝘳𝘵𝘶𝘳𝘦! [𝘊𝘖𝘕𝘊𝘌𝘙𝘛 𝘉𝘈𝘕𝘋] (𝘏𝘶𝘯𝘵𝘦𝘳 𝘹 𝘏𝘶𝘯𝘵𝘦𝘳 2011) Sheet music for Trombone, Euphonium, Tuba, Flute piccolo & more instruments (Concert Band)13 janeiro 2025 -

Honda lança modelos CG 160 Titan e CG Fan da linha 202313 janeiro 2025

Honda lança modelos CG 160 Titan e CG Fan da linha 202313 janeiro 2025